Our Infrastructure

Our company has 1 rice mills, which are located in Pali (Khopoli), India. Both the mills are equipped with the most advance technologies. The mills are equipped with Miltec machinery and are PLC Plant which helps us get the best quality and production capacity at the same time. Our daily production amounts to 5 MT per hour..

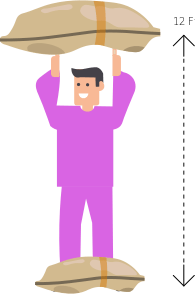

The process of parboiling uses treated soft water obtained from our water treatment plants. The parboiling plants have specially designed soaking bins with sensors based on sophisticated controller for maintaining and determining the water temperatures. The advanced parboiling method ensures that the grain is free from unwanted smell and confirms to most hygienic processing of the grain, preserving its natural fragrance & aroma during the entire process. We have adopted special methods of parboiling, as the paddy is kept for soaking for 12 hours, we keep changing the water after every 4 hours, keeping the temperatures controlled by not letting the water go below 60 degrees centigrade and the inlet water is also changed every 1 hour so that there is no bacterial formation, thus ensuring the best hygienic & parboiled rice always. these minute steps ensure 100% quality of rice for the end user..

Our professionals team of employees make sure 100% quality control, right from the stage of procurement of paddy, milling, parboiling, the cleaning process, packaging and logistics. Our rice mills are a stage of art and are fully equipped with pre-cleaners, de-huskers, polishers, sortex, silky, rice bins and magnets to completely protect the food process against contamination and other impurities during the food process of milling. All the latest machinery and technology is imported from Japan & United Kingdom and our company also keeps upgrading the working system every year.

Our Labs are fully equipped with advanced and latest machine to check the quality of every and each grain of rice. Our professionals team of employees make sure that we get the best product with 100% quality control. To make this possible our team tests the paddy and rice at every step of processing. Our Laboratrarian are well experienced who does not pass any single piece of rice grain from the laboratory if it is failed in quality test. Thus our Laboratrarian plays a vital role to insure the quality of our products.

As we are a leading manufacturer and distributor of Basmati Rice and Non Basmati Rice we have huge warehouse facility to hold large stock of all kinds of Basmati and Non-Basmati rice. Our warehouses are well-maintained to sustain the quality standards during the period of storage. In fact, the large stock of products has helped us to cater to the demands of the customers even in the period of crisis. The rice is stored in the warehouses of the company, which are spacious and well ventilated. A vigilant staff ensures hygienic conditions in the warehouse. Further on, regular inspection and fumigation is carried out to prevent any kind of infestation against various microorganisms.

We have our own Logistics systems. We have our own Trucks to deliver our sacks of rice in different areas of country.

We are distinct.

Expanding the Horizon with various ranges of Products.

2

20000+

40+

1000+

PROCESSING OF RICE

SOURCING

Sourcing is done from the original basmati habitat where the grain is nurtured by crystal clear Himalayan snow melt.

FORM OF RICE

Multiple forms of rice are processed differently: raw, steamed & sella rice.

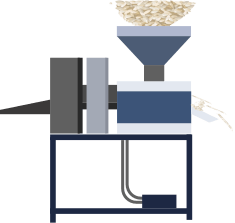

MILLING OF RICE

World class milling ensures aroma, taste and texture with superior polish and whitening process.

REMOVAL OF IMPURITIES

Color sortex machines remove impurities & graders separate broken and immature grains.

PACKING & LOADING

Export-grade packing, fumigation & hygienic loading is done at Gujarat warehouses.

RICE PRODUCTION FLOW

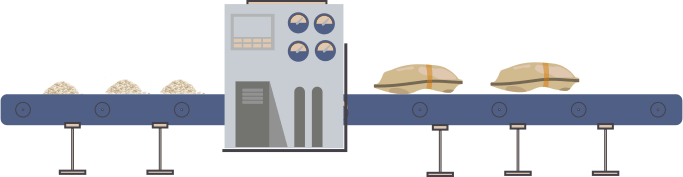

The basic rice milling processes consist of:

RICE PRODUCTION FLOW

HOW IT WORKS

1. Pre-Cleaning: Paddy cleaner removes impurities like dust, straw, sand, clay, and heavy particles. Increases life of rubber rollers and improves bran oil content.

2. De-stoning: Separates small stones from paddy.

3. Husking: Dehusker machine removes husk using centrifugal principle.

4. Husk Aspiration: Separates husk from brown rice/unhusked paddy.

5. Paddy Separation: Unhusked paddy separated from brown rice.

6. Whitening: Removes bran layer and germ to convert brown rice to white rice.

7. Polishing & Grading: Improves appearance, removes residual bran, separates small/large grains, blends as per customer requirement.

8. Weighing & Bagging: Prepares milled rice for transport with accurate weights and automated stitching.